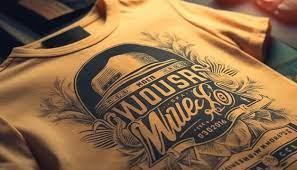

“Direct to film” is referred to as DTF. It is a superior substitute for other full color textile transfer films and a cutting-edge product in the textile printing industry. Printed on a transfer film, DTF transfers are a unique kind of iron-on image that may be ironed or heat-pressed into textiles or other surfaces. DTF transfer films don’t need a unique ink coating on the carrier media, in contrast to conventional transfer films.

Rather, the transfer film is coated with a small layer of white or transparent powder and printed using a specialized DTF printer. Using heat and pressure, the printer applies water-based inks to the powder, which are subsequently applied to the target substrate. DTF transfers produce prints with exceptional quality and detail since they have a high print resolution and wide color gamut. They are an excellent option for branded apparel, promotional products, and gifts since they are strong and resistant to washing.

How DTF Transfer Work in Fashion?

DTF transfers have their roots in the demand for more effective and adaptable printing techniques. The development of technology has been essential in improving DTF transfer methods and increasing their applicability and accessibility in the fashion industry.

For many reasons, fashion manufacturers are keen to adopt DTF transfers. The production landscape has been completely transformed by the process’s cost-effectiveness and quick customization of designs. The quick turnaround time of DTF transfers gives businesses a competitive advantage in the quick-paced fashion sector.

Types of Custom DTF Prints in Women’s Fashion

Women’s clothing can be made more stylish and vibrant with the use of different kinds of DTF prints. Here are a few well-known ones:

Floral Prints

Women of all ages are drawn to floral designs because they have a revitalizing quality. It makes sense that flower prints are a favorite among fashion designers, especially for their spring and summer collections. Bright floral prints are cheerful and cheerful, which makes them a great option for summer clothing.

Geometric Prints

Geometric prints are repeating images of geometric shapes that might be subdued or elegant, or they can be bright and striking. Geometric prints employ a wide range of shapes, such as squares, cuboids, houndstooth, stripes, and triangles, to create intricate symmetry and interlocking patterns that truly stand out.

Since these shapes give an ensemble depth and dimension, a geometric print should naturally be the focal point of your ensemble. Pair it with simpler items to let the pattern of your geometric print do the talking.

Abstract Prints

This may be the trend for you if you want to add some fun, colorful attire to brighten up the summer months! A general style for summer and all seasons is bold abstract. It draws inspiration from vivid street art, graphic design, and color blocks. Young fashion or the younger market would benefit greatly from this trend.

The new artistic abstract fashion is very effective, appealing, and liked by everyone. It is accessible in all contemporary categories, including women’s, men’s, kids, casual, formal, parties, and loungewear.

Animal prints

Numerous animal prints are available, such as textures of snakeskin and crocodiles, as well as images of leopards, cheetahs, zebras, tigers, cows, and giraffes. The most prevalent animal print style, seen in coats, bags, and other items, is leopard print, which has stayed in style for decades.

Advantages and Limitations of DTF Transfer in Woman’s Fashion

Advantages

1. High Quality Prints

A level of quality and detail that is difficult to achieve with traditional printing methods is provided by DTF printing. It may produce intricate, delicate patterns with precise lines and details. On the other hand, screen printing is constrained by the number of screens that are utilized. In addition, DTF printing uses white ink as a base. Vibrant colors may now be printed on dark fabrics, something that is previously impossible with other printing methods.

2. Versatile

DTF printing is an incredibly adaptable printing method that works well with a wide range of materials, including polyester, cotton, and more. Designs for custom dtf transfer for t-shirts and apparel and printing original designs on t-shirts, sweatshirts, jackets, caps, and bags, this makes it the ideal choice. The color of the fabric likewise has no bearing on this printing technique. This makes it an excellent choice when printing on vivid or dark materials.

3. Easy to use

DTF printing is an easy printing method that requires minimal expertise to use. DTF printing can be done by anyone who has a basic understanding of the printing process. However, screen printing requires a high level of technical know-how and proficiency.

4. More Durable

The durability and tensile strength of DTF printing are well-known. We apply a special powder adhesive to the cloth before the pattern is printed on it. This glue creates a strong bond between the ink and the fabric in prints. This is not easily broken, peeled, or faded.

Read: The Rise Of Gender-Neutral Fashion: Breaking Barriers In Style — Sticky

Limitations of DTF Prints

1. Limited Color Range

One of its main disadvantages is the limited color selection. DTF printing is not the ideal choice for printing designs that require complex color gradients or a wide range of colors. This is due to the fact that DTF printing applies a powder adhesive on the design prior to transferring it to the fabric. The number of colors that can be utilized in a design is limited by the amount of ink that the powder adhesive can hold.

2. Long Process Time

Compared to other digital printing methods like Direct-to-Garment (DTG) printing or screen printing, DTF printing requires more time to finish. Screen printing can produce multiple prints rapidly, but DTG printing can produce a single print in just a few minutes. However, a single print using DTF printing could take up to an hour to finish.

3. Environmental concern

This brings us to our next digital printing constraint. Many environmental concerns are brought up by the DTF printing process’s use of chemicals and powders. Before being transferred to the cloth in DTF printing, the pattern is covered with a powder adhesive. The ingredients in this powder glue could be . harmful to the environment if not disposed of appropriately.

4. Limited scalability

One drawback of DTF printing is the restricted scalability of the technology. If we consider the time and effort required to create the artwork and print each item of clothing, then small to medium print runs are reasonable. Manufacturing can expand by adding printers and heat presses, but not by increasing speed or efficiency.

Exploring Design Possibilities Using DTF Transfer

1. Filtered Design

The task specifications should be taken into consideration when designing a DTF filter. The intended frequency response, including the ripple, attenuation, stopband, and passband, must be defined. It is also necessary to take into account the filter’s latency, memory needs, and computational complexity.

2. Frequency Response

The most crucial factor in assessing a DTF filter’s performance is its frequency response. It displays the effects of the filter on the input signal’s phase and amplitude at various frequencies. A DTF filter’s frequency response can be plotted using the gain and group delay, or the magnitude and phase responses.

3. Time Response

An additional criterion for assessing a DTF filter’s performance is its time response. It displays the filter’s response to several input signal types, including steps, sinusoids, and impulses. An impulse response or step response can be used to plot the DTF filter’s temporal response. Using the filter coefficients and the convolution of the input signal, you can also compute the temporal response.

Future Outlook and Innovations in DTF Printing for Women’s Fashion

Among the printing technologies with a promising future is DTF printing. Innovations in the manufacturing of textiles, in particular, will advance this kind of printing and redefine how direct to film printing can change everything. Because of this, interesting trends that will influence DTF’s future are already being predicted.

- More Advance Resolution

- Serial Printing Process

- Extend Color Scale

- Revolution in Fashion Technology

- Augmented Reality Integration

Conclusion

DTF printing offers a creative and dynamic means of producing vivid, long-lasting personalized graphics on a range of textiles. DTF is a recommended printing process for anyone looking to upgrade their clothing decorating because of its exceptional quality, adaptability, and eco-friendly features. With custom DTF transfer for t-shirts and apparel, the possibilities for creative expression are endless. DTF transfers open up a world of creative expression options for anyone, be it an individual seeking to personalize garments or a business owner wanting to tailor your offerings.